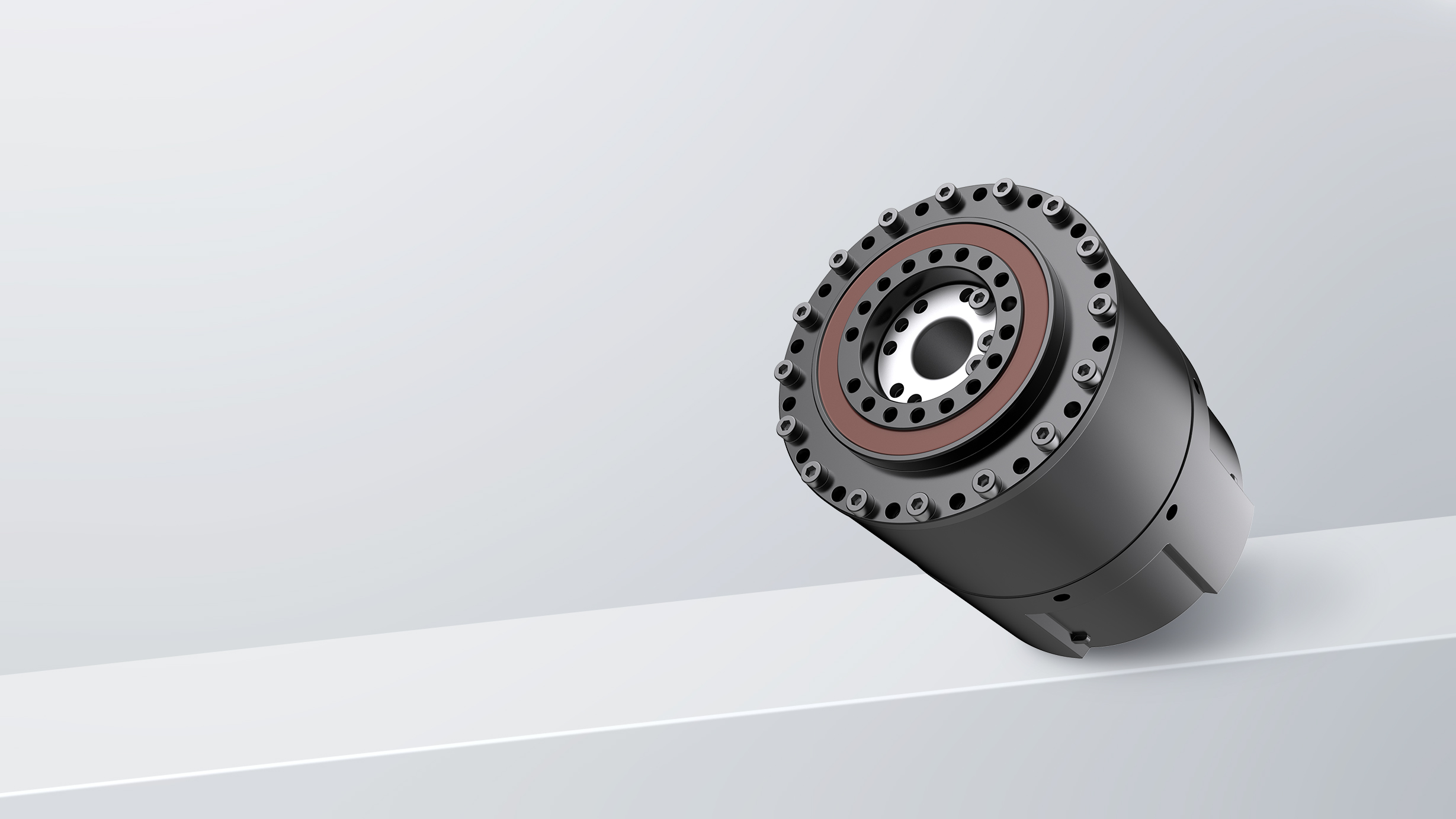

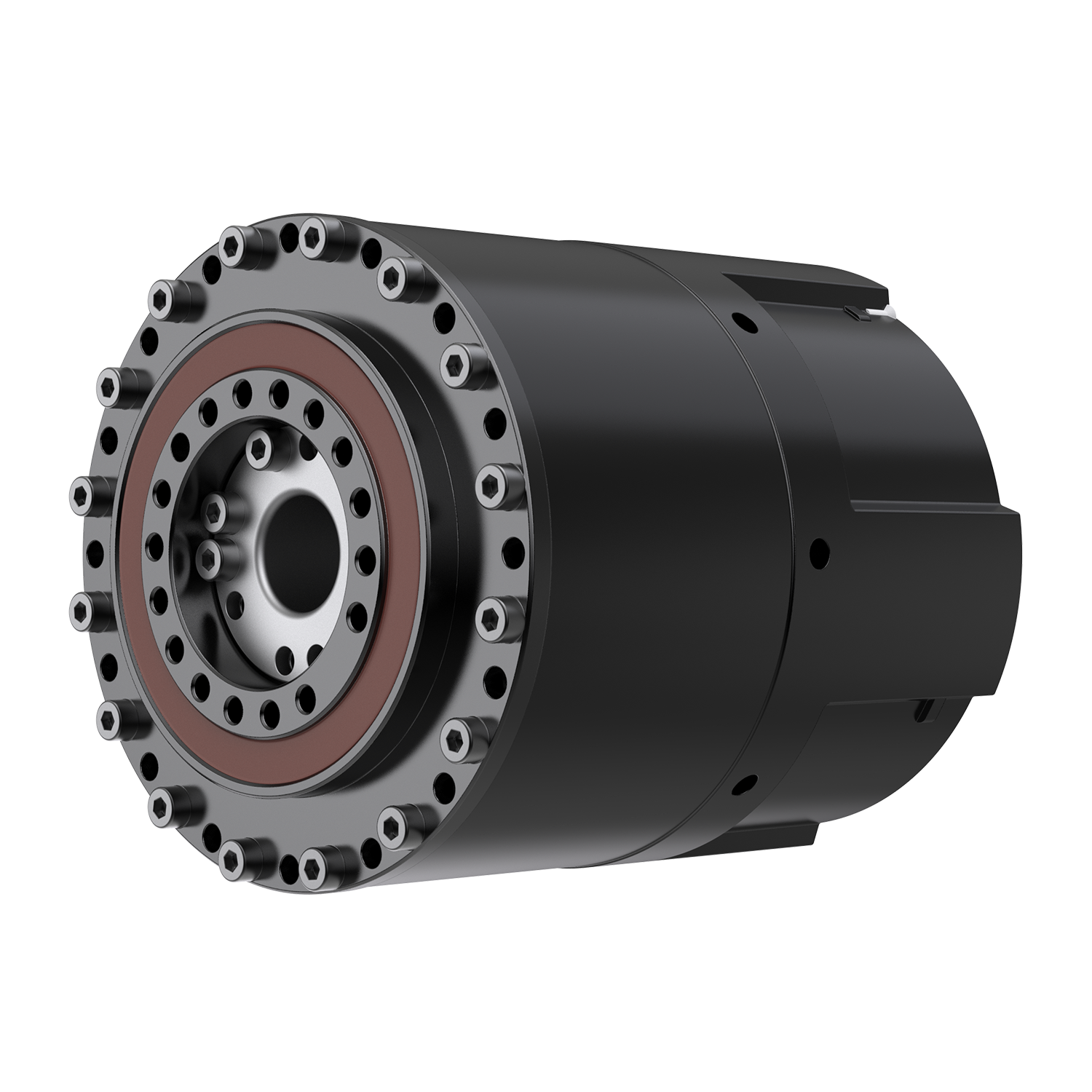

H70

- Equipped with flexible adaptive joints

- Features high-precision, high-rigidity industrial-grade cross roller bearings

- Incorporates lightweight design and compact radial structure with 12mm hollow shaft

- Supports EtherCAT and CANOpen communication protocols

- Provides multi-loop PID control (position, velocity, current)

High-torque dynamic response feedback

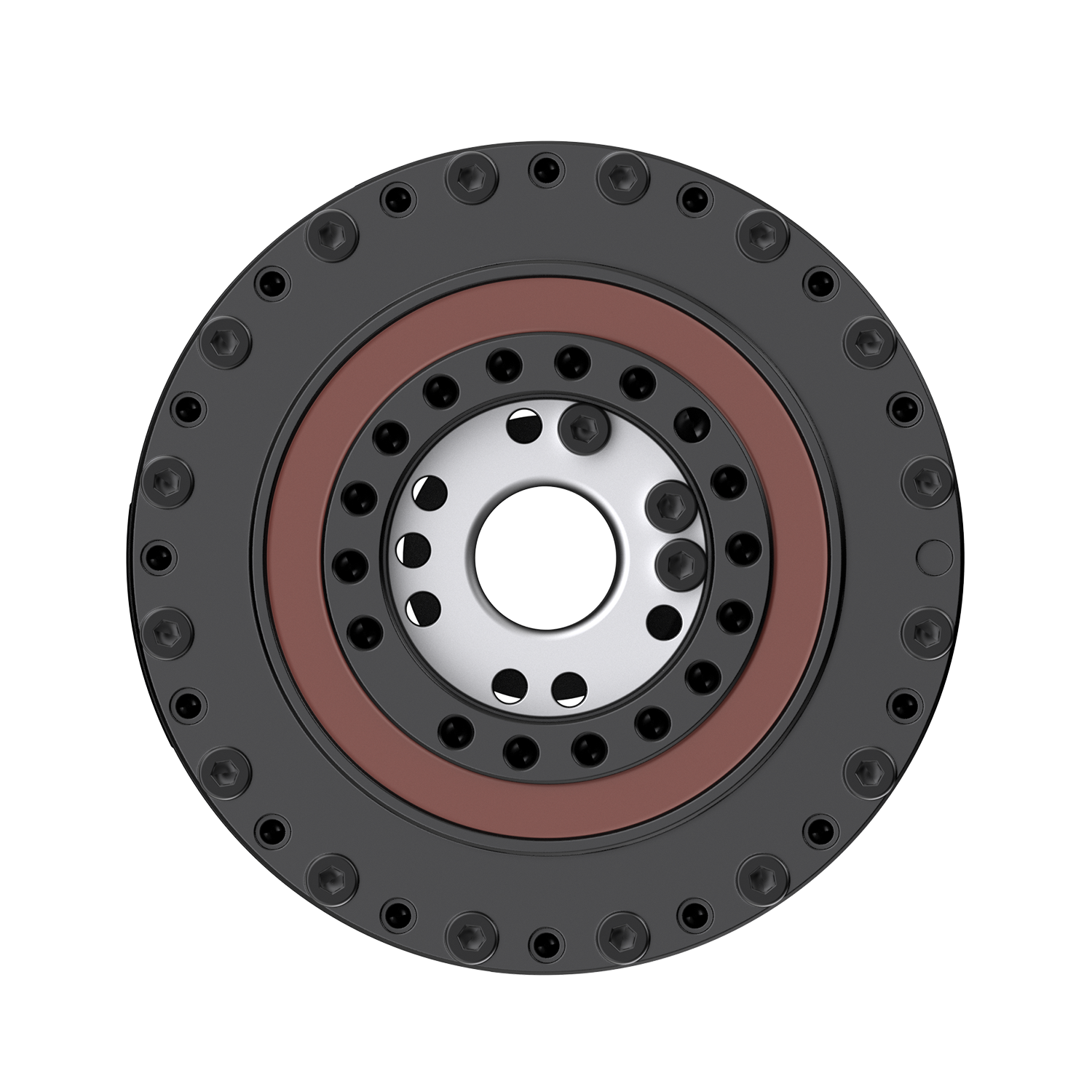

Large hollow bore design

High-precision torque sensor

Multi-protocol high-speed communication support

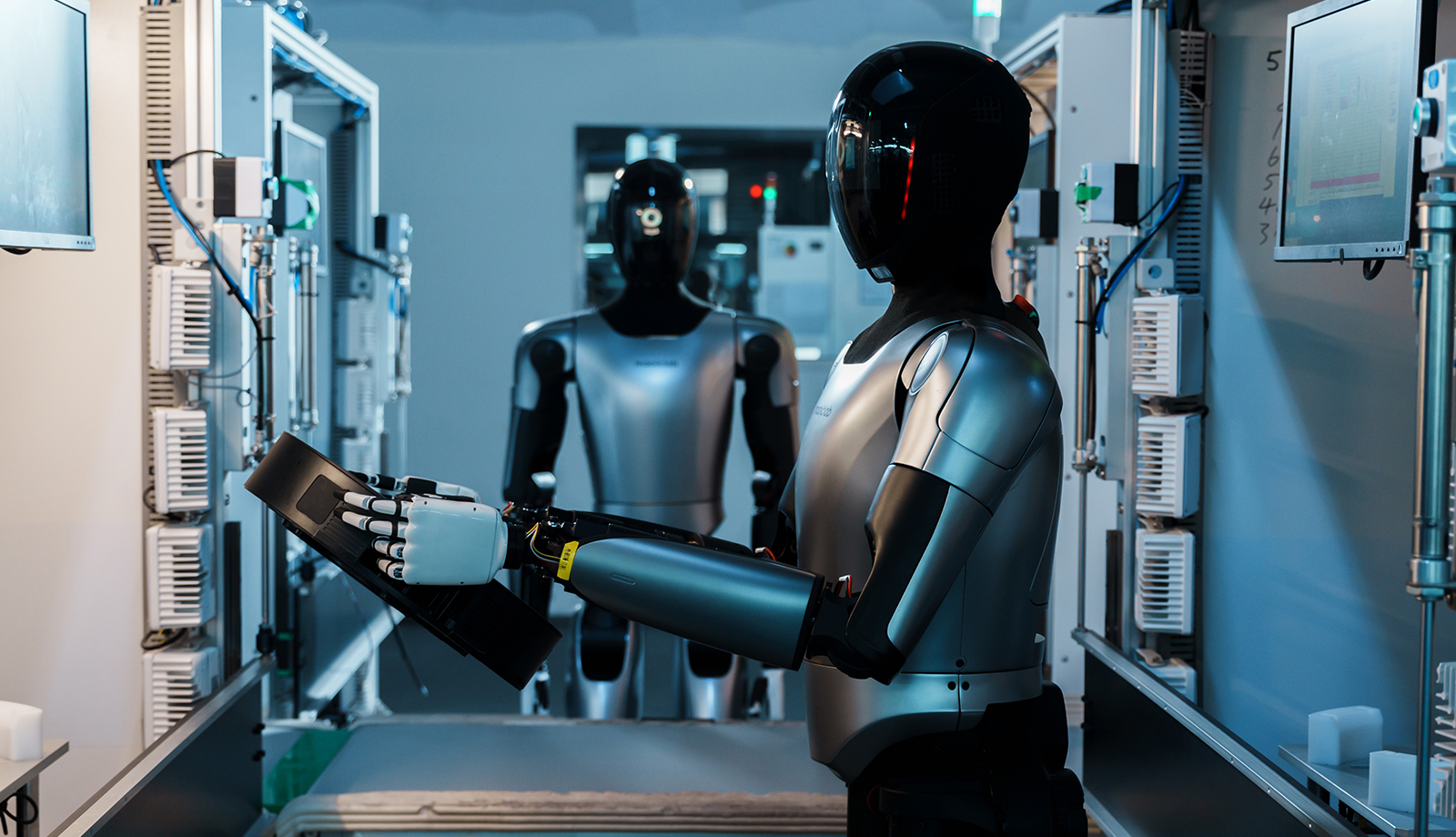

Precision Collaboration, Flexible Empowerment

High-strength custo mized harmonic drive with integrated high-precision torque sensor enables millimeter-level flexible control.

providing robust support for delicate operations while empowering robots with safe collaboration and intelligent perception capabilities.

High-Torque Drive Core: Empowering High-Performance Robotics

Compact yet Powerful, engineered specifically for high-performance robotic systems, H70 delivers stability to critical components like robotic arms.

High-torque output enables precise control and powerful operation.

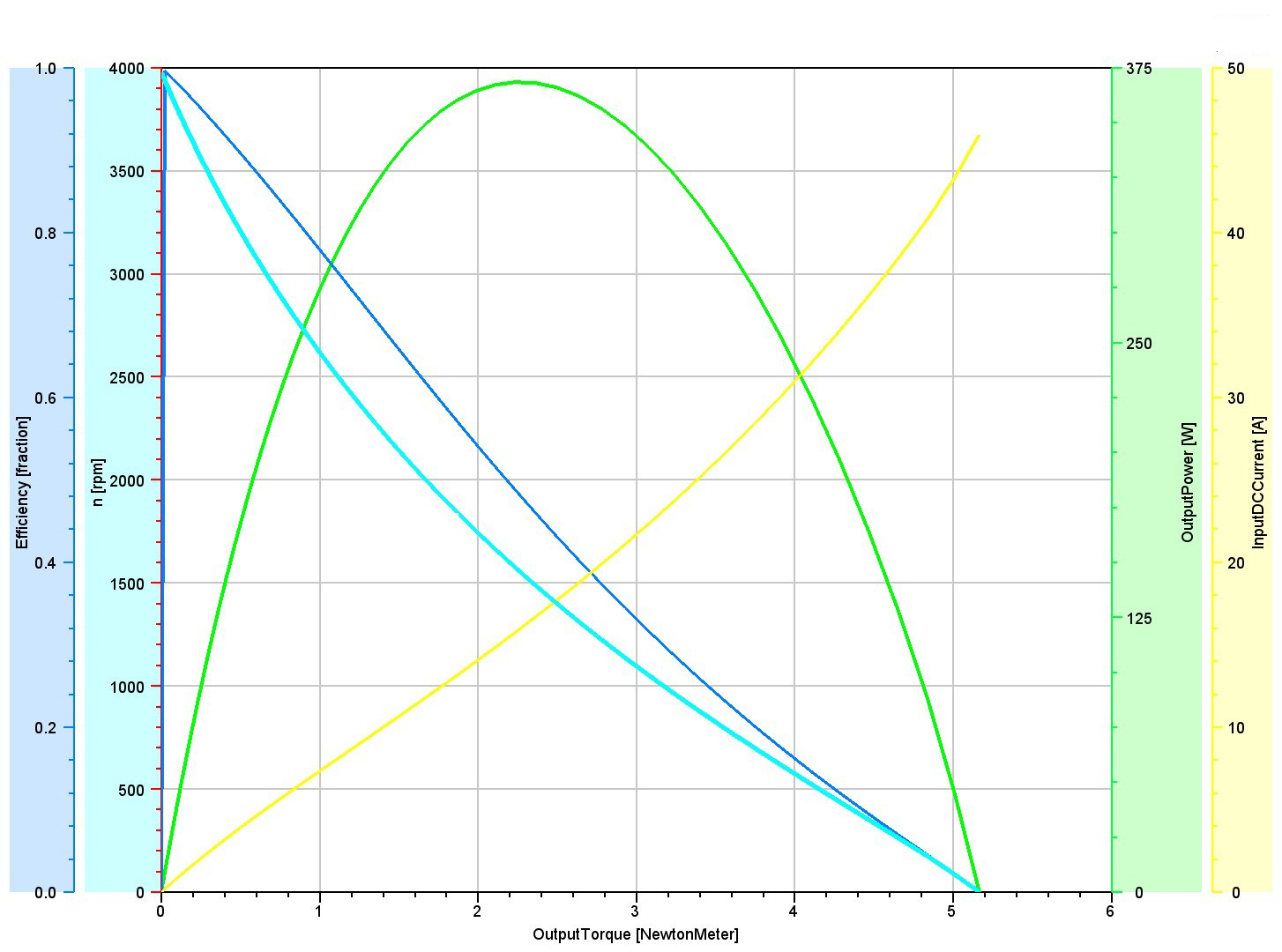

Optimized design of flux density, selection of optimal pole-slot fitReduction of harmonic distribution coefficients and elimination of tooth harmonics

Motor Control Characteristic Curve

产品参数

Gearbox Type

Harmonic Gear

Maximum Speed

30rpm(48V power supply)

Module Weight

900g

Rated Torque

30N.m

Dimensions

φ70*96

Peak Torque

96N.m

Communication Interface

CAN/EtherCAT

Peak Current

11A

Recommended Operating Environment

-5℃~40℃

Encoder Configuration

Dual Encoder

Operating Voltage

48V-54V

Motor Encoder Resolution

19Bit

Control Frequency

25,000Hz

Motor Feedback

Torque, Angle, Angular Velocity, Temperature

Control Modes or Commands

Torque, Angle, Angular Velocity, Stiffness, Damping

45° Angle

Front View

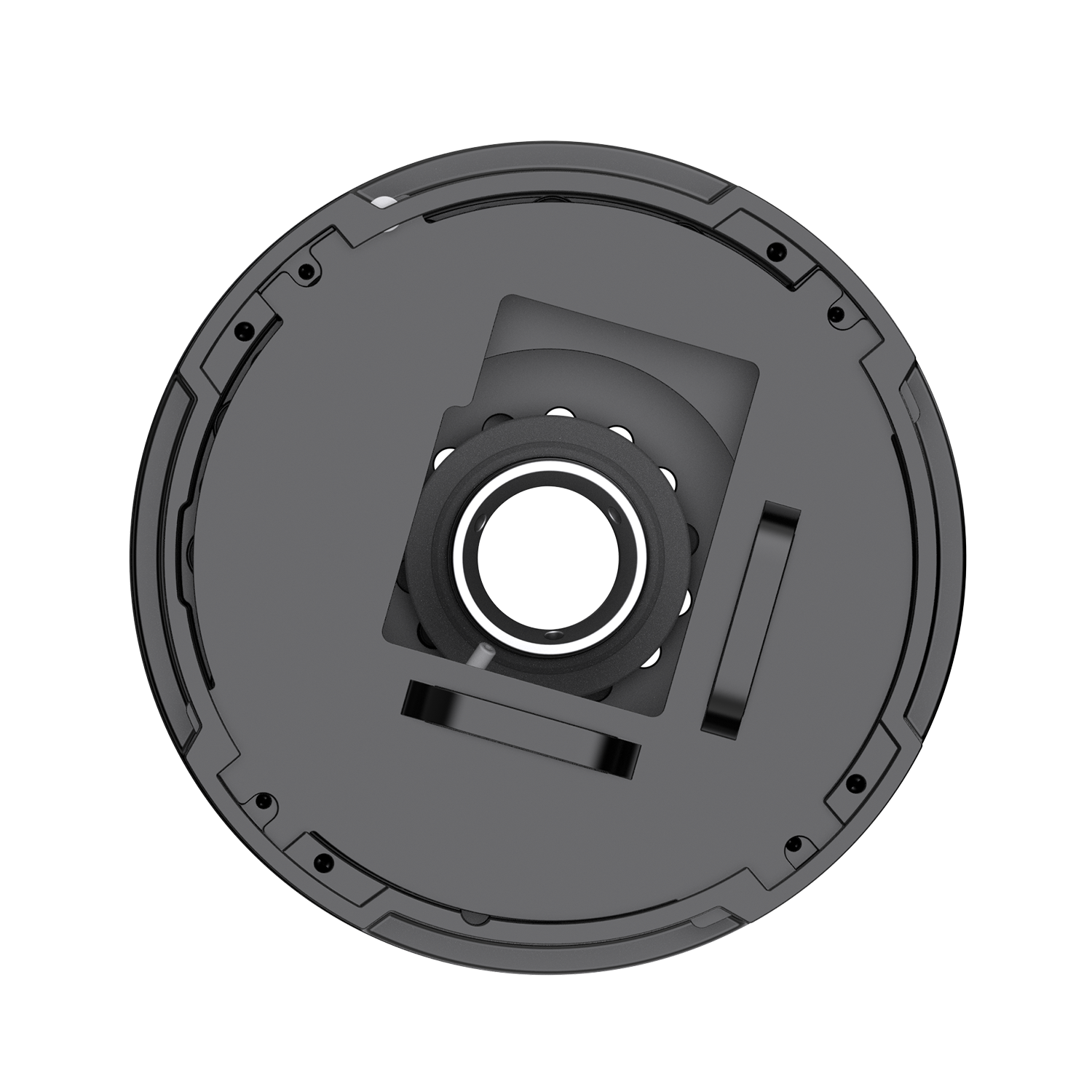

Rear View

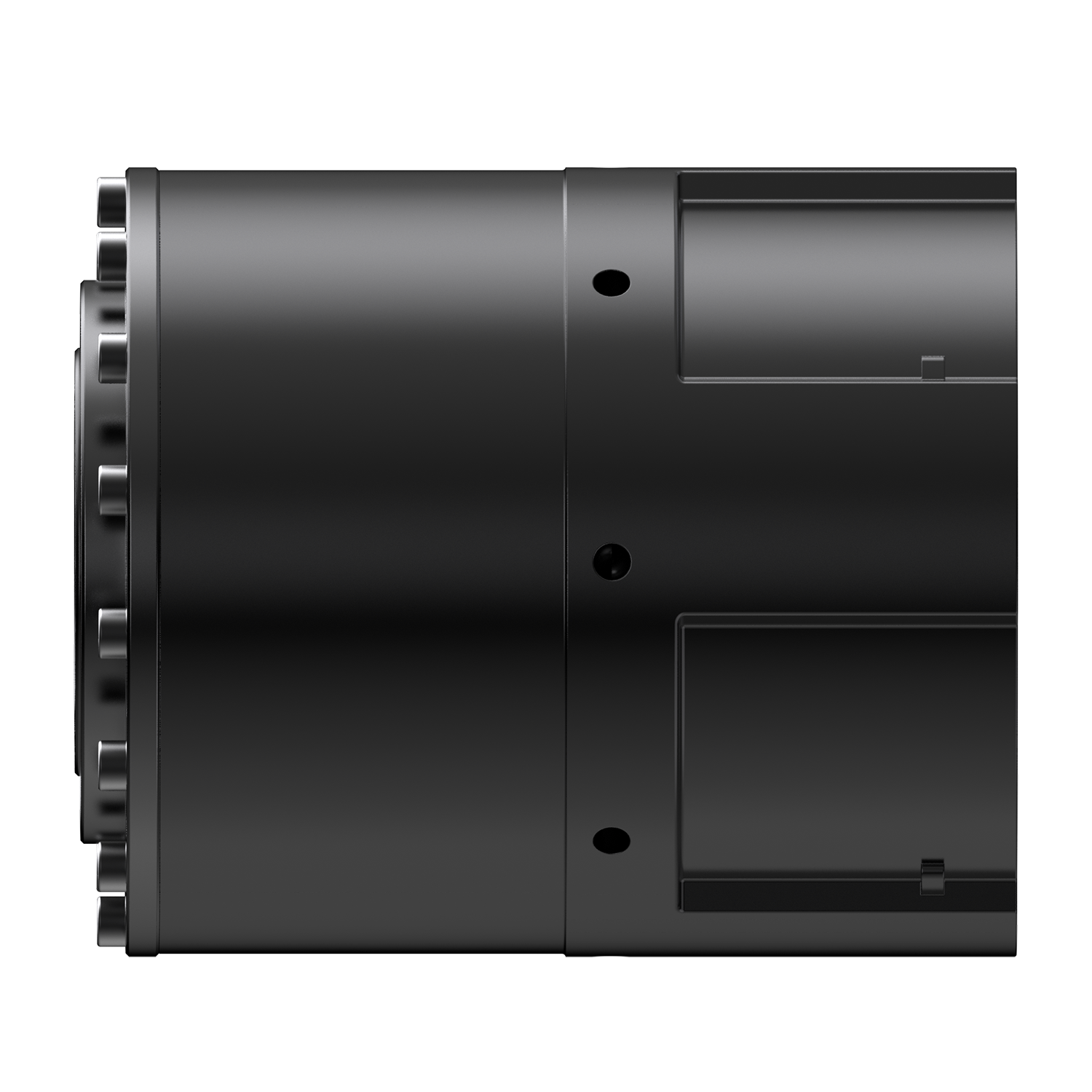

Side View

Top View